Reliability is critical in all modern automotive and industrial applications. Ranging from automotive zonal control units or computer numerical control in industrial applications, no matter how simple or complex the end product is, if it cannot be relied upon then the manufacturer’s reputation will almost certainly be damaged. Added to this are the costs of warranty repairs and even possible recalls.

However, electronic circuits will fail eventually, possibly due to external influences or as components degrade over time. In these situations, good design practice recommends the inclusion of circuit protection devices that will ensure that the effects of failures are minimized.

This article illustrates the limitations of standard circuit protection devices and how e-Fuses can be used to improve designs.

Probably the most common (and lowest cost) form of circuit protection is the humble fuse. These are based upon metal wire or a thin metal strip that has a low temperature melting point. Fuses are normally inserted into the power feed, and when excess current flows, the heat generated in the fuse causes the wire / strip to melt. Consequently, disconnecting the power source from the circuit.

This disconnection is not usually instantaneous, and the time taken for a fuse to “blow” is in inverse proportion to the fault current. If the current is only slightly above the fuse rating, it may flow for some time, influencing the power rail causing malfunction or damage to the circuit.

Fuses are not convenient; once they have blown, they need to be replaced (normally by the user). If the wrong rating is (inadvertently or deliberately) used, then this represents a fire hazard.

Other devices such as positive temperature coefficient (PTC) thermistors may be used. These PCB-mount devices increase their resistance as temperature increase, thereby limiting the current flowing. Provided the overcurrent is not excessive (otherwise the PTC thermistor would go open-circuit) as the current diminishes, the temperature falls, and normal operation returns.

While this overcomes the need to replace a fuse, PTC thermistors are non-linear and not well suited to use over a wide temperature range caused by principle of its operation.

e-fuses

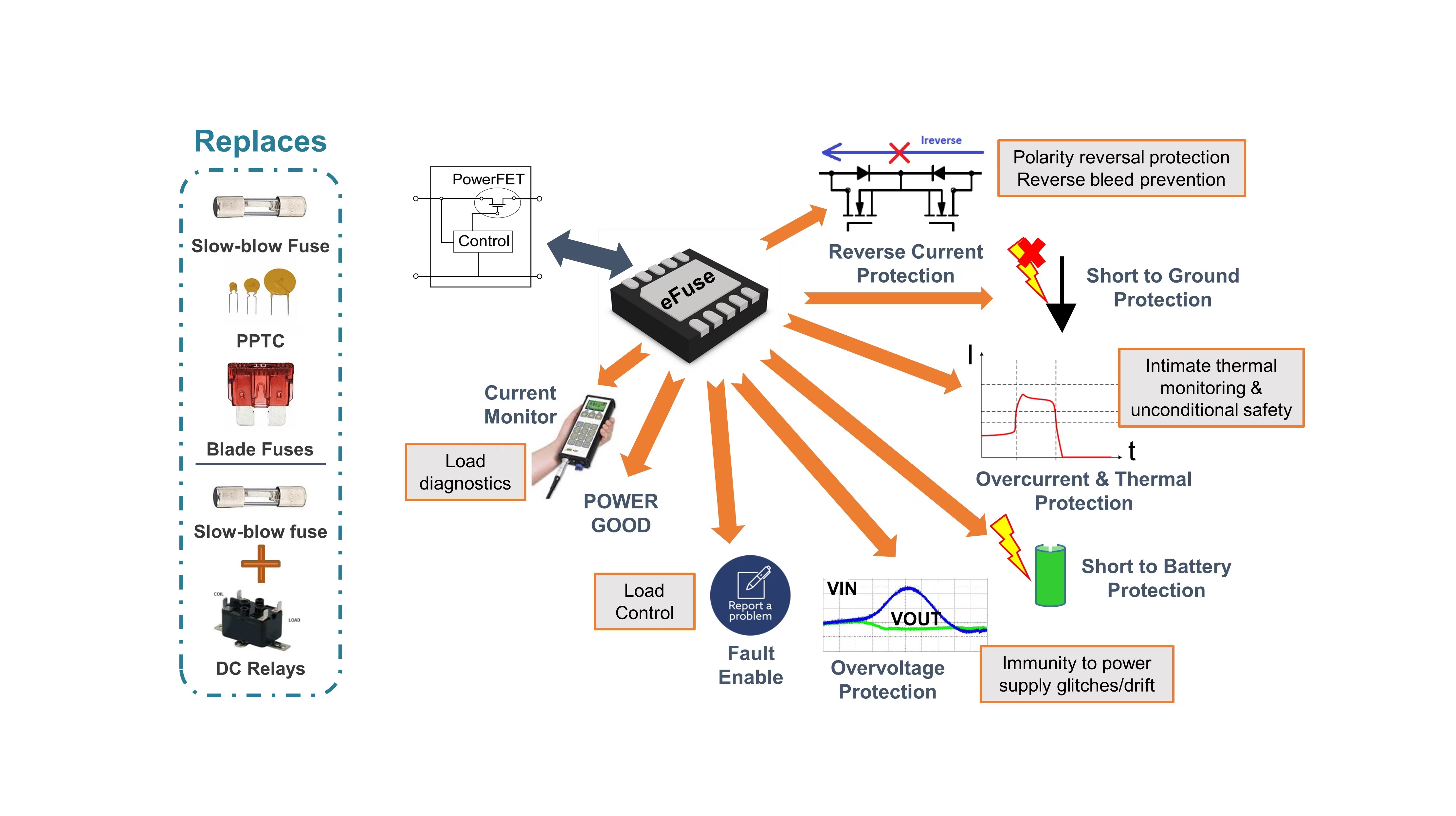

Electronic fuses (or “eFuses” – a term coined by onsemi when they released the first devices to market) are a modern alternative that offer basic circuit protection – and a lot more functionality. Typically, they include protection against overcurrent including shorts, overvoltage, reverse current, and excessive thermal rises.

While there are many applications for these innovative devices, they are commonly used in hot-plug situations, or anywhere power glitches are common. They are also used where there is a significant possibility of a load fault or in systems where an inrush / outrush current limit is needed.

Enable pin in combination with high precision current control mechanisms turns this device into combo of load switch and fuse as a basic building block of point of load control systems in modern distributed power architectures.

The primary advantages of eFuses are their flexibility and ability to self-reset, eliminating the need for user intervention. As intelligent devices, their additional features enable additional functionality within systems, beyond just overvoltage / overcurrent protection (which they excel at).

For example, many eFuses include a power good (“PGOOD”) pin that can be used with a system controller to precisely sequence power rails. Some eFuses include tristate pins that can be used to ensure simultaneous turn on / off multiple power rails.

The ability to detect reverse current (something a traditional fuse cannot do) makes them useful in redundant power applications where ORing is required. This is also valuable where a large capacitor is required to retain charge after a system is shut down, often to limit inrush current upon startup.

Figure 1: eFuses offer a wide range of features to enhance protection.

In many applications, capacitors (or capacitive loads) can be a challenge, causing large inrush currents that may damage components or PCB traces. eFuses can offer several features to assist designers in dealing with this such as auto-retry, or inrush current limiting to allow the capacitor to charge in a managed way.

As intelligent devices, eFuses can monitor temperature, voltage, and current, passing this data to a system controller. This is particularly useful to detect changes that may be an early warning of impending failure.

eFuses in automotive applications

As more technology is included in all vehicles, the need for adequate circuit protection increases to ensure reliable operation and to prevent damage. This is especially necessary in vehicles as the current capability of batteries is sufficient to destroy delicate electronic components.

eFuses are commonly used in the power line to sub-systems (such as heads up displays or infotainment) to disconnect and shut down these systems in the event of a fault.

In systems that are partially external to the vehicle, damage to the external elements could cause a short circuit that would damage internal circuitry. One such system is the telematics where the external LNA and GPS antenna are connected via eFuses, protecting circuitry within the vehicle.

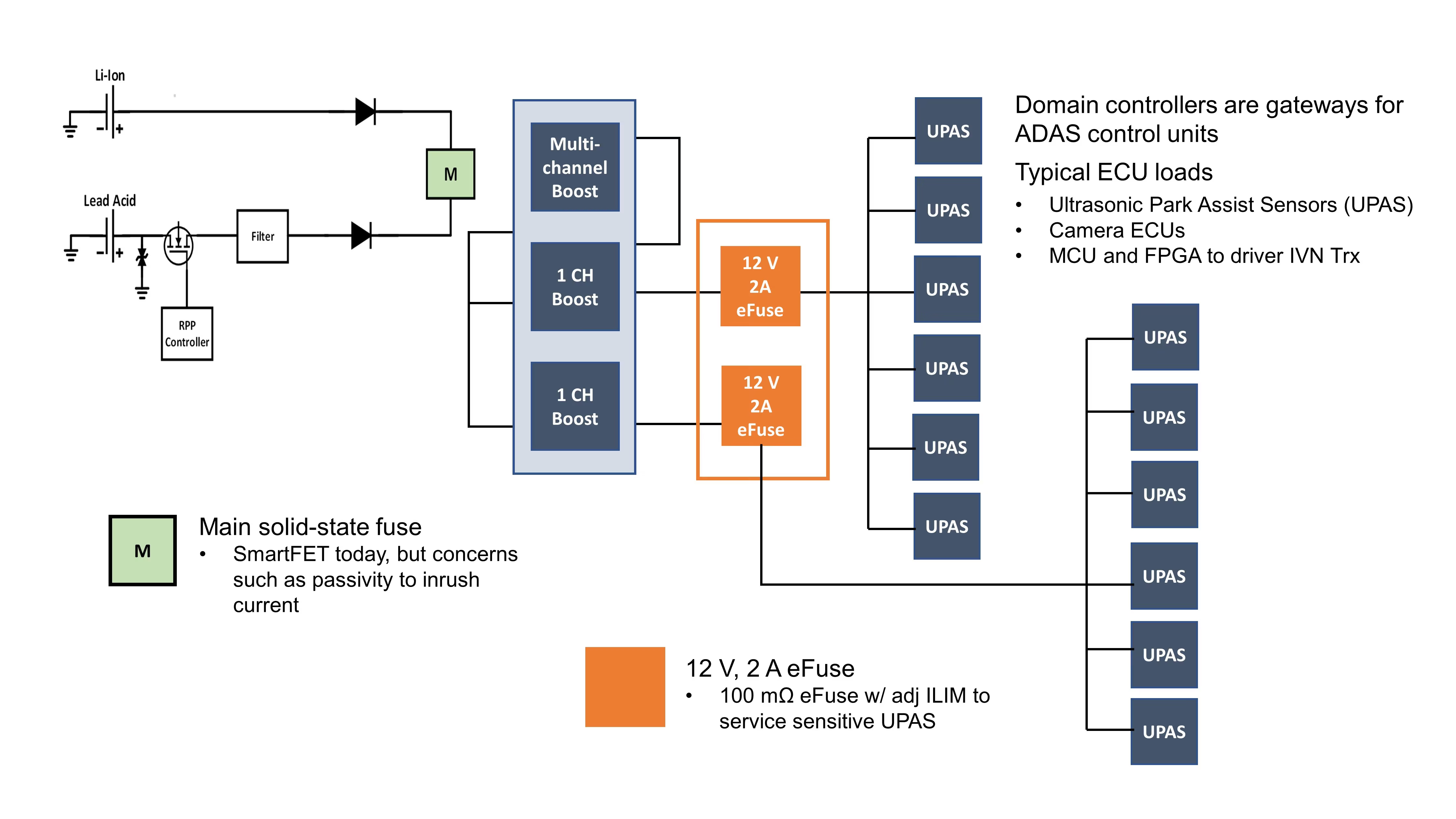

Where vehicle systems are divided into zones, then eFuses may be cascaded within the system, offering overall protection as well as protecting sub systems.

Figure 2: Cascaded eFuses are sometimes used in zoned automotive applications.

For example, in an ADAS domain controller, a main fuse may be connected between the power source and the main system while secondary fuses could be used to protect system peripherals, such as the externally mounted ultrasonic park assist sensor units.

The wiring harness in modern vehicles is a complex sub-system. It is expensive and difficult to replace once the vehicle is assembled, so protection is vital. Many power-hungry devices (fans, window motors, air conditioning, other actuators) are connected to the harness. A fuse is generally used before these systems to protect the harness in the case of failure leading to excessive current draw.

Examples of latest technology in eFuses

The NIV(S)3071 from onsemi is a 60 VDC, 65 VTR, eFuse that integrates four independent channels into a single 5.0 mm x 6.0 mm package, with each channel supporting currents up to 2.5 A continuously (10 A total). The RDSon value for each channel is just 80 mΩ, ensuring minimal loss within the eFuse.

There is a configurable current limit that is common to all channels, other features include digital flag to indicate a fault, configurable current trip time, and soft start.

With the ability to operate at junction temperatures (TJ) from -40ºC to +150ºC and 2 kV of ESD protection, the NIV3071 is ideally suited to demanding automotive applications, both 12 V and 48 V.

The NIV(S)4461 is a single eFuse providing overcurrent, undervoltage, and inrush current protection in applications such as industrial automation, telecom, computing and more. The device can support continuous currents up to at voltages as high as 30 V.

Notable features of the device are its low resistance (Typical RDSon = 39 mΩ) and fast trip time. The device also includes a programmable current limit (1-7A), undervoltage and adjustable slew rate control. User configurable features include latch-off, auto-retry

The NIV(S)4461 is housed in a DFN10 package measuring just 3.0 mm x 3.0 mm. It has an industry standard pinout and is compliant with UL2367 and IEC62368.

Summary

Circuit protection is an essential element of modern design, ensuring reliability of circuits and systems and minimizing damage when failures or unexpected conditions occur.

While traditional fuses offered some protection, modern eFuses offer greater accuracy, more flexibility, and wider feature sets that significantly improve the protection achieved.